Health And Safety Information

Safe working practices should always be adhered to at all times during the construction process and all necessary Personal Protective Equipment (PPE) should be worn.

Ground Preparation

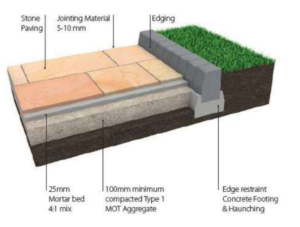

For most domestic applications, a sub-base of approx. 100mm (4”), with a 35-45mm mortar bed should prove to be sufficient. However, the paving design must be based upon the prevalent ground conditions, ground type and anticipated loads. If the ground is very soft or if the paved area is going to have heavy traffic on it, you would need to allow for a depth of 200mm of hardcore and 100mm for the slab & mortar thicknesses. It is necessary to provide a permeable sub-base as to allow adequate drainage for the paved area, as prevention to do so may adversely affect the finish to the stone surface and may prevent the stone from drying out properly following periods of getting wet. (i.e. following rain, etc)

Laying The Paving

1: Paving slabs should be cleaned of any dirt/debris prior to laying. This is to remove any dust, loose material, packaging or production aids. To avoid damaging the stone, stack the slabs on timber battens with spacers or similar.

2: An SBR Bonding agent or Primer Slurry, should be painted to the back of each paving slab prior to laying, to prevent any moisture from coming up through the paving from the mortar bed beneath.

3: Lay the paving slabs on a full mortar bed, which should support the entire slab, not just on the corners or in blobs. The mortar should be made up of 6 parts sharp sand & 1-part cement. Mix together with just enough water to make the mortar damp & workable, but not overly wet or runny.

As you are laying the slabs, keep checking levels and gradient across the units. String lines can be helpful to define levels and lines within the laying pattern. Maintain the correct joint width by gently shuffling with a trowel. Small pieces of timber are useful as temporary spacers. All paved areas should be laid to a small fall, to prevent any pooling of water on the surface of the paving.

As you are laying the slabs, keep checking levels and gradient across the units. String lines can be helpful to define levels and lines within the laying pattern. Maintain the correct joint width by gently shuffling with a trowel. Small pieces of timber are useful as temporary spacers. All paved areas should be laid to a small fall, to prevent any pooling of water on the surface of the paving.

Cutting

Cutting may be carried out using a diamond tipped power saw, or hammer and bolster. It must however be noted that the aesthetic finish achieved will depend greatly upon the choice of cutting mechanism and level of skill.

Inclement Weather

Laying operations should be discontinued (and any open work face covered) if weather conditions are such that the performance of the paving may be jeopardised. Laying operations should not be undertaken when the temperature is below 3ºC on a falling thermometer and below 1ºC on a rising thermometer. All unfinished areas and stockpiles of materials should be covered in the advent of inclement weather to prevent saturation.

Grouting

There are several products on the market for the grouting of paving products. Resin based jointing products such as Stone Joint, or a cement and mortar mix, are examples of these. We recommend that paving is laid allowing for a minimum 5mm joint. If you are using a jointing product please follow the instructions on the cover of the product, as failing to do so could lead to products failing to function correctly.

For most paving types, Stone Joint Brush-In Grout or Flowpoint Grout can be used where a minimum of 5mm joint and minimum 20mm thick paving slabs are being utilised. Alternatively use a damp mortar mix of 1-part cement to 4 parts building sand. If mortar/grout gets onto the surface of the units, clean off immediately using a damp sponge or similar frequently rinsed in clean water.

Under no circumstances should dry or semi dry sand/cement mixes be brushed into the joints. This practice can lead to staining of the paving and does not constitute a true rigid joint. If a narrow 5mm joint is desired then a gun applied mortar compound may be used to fill the joints or a good quality external grout should be considered. Butt jointing is not recommended for any of these paving products.

Disclaimer

Boyle Patio cannot accept any responsibility for any mortar staining, or any problems regarding cutting/laying of any of their paving products.

All natural stone paving products are subject to colour variation, due to natural variations in all stone products.

All sizes and dimensions stated are approximate, and are subject to variation due to natural variations in all stone products.